DOURRY INTELLIGENT

Email: lydia@dourry.com

WhatsApp: +86-18768866269

aluminum plate, carbon steel plate, stainless steel plate, galvanized plate, yellow copper plate

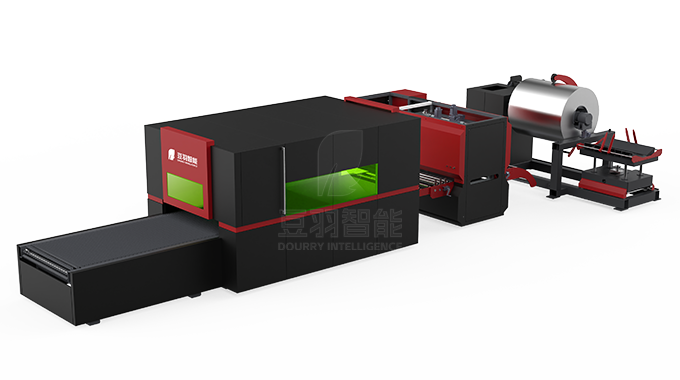

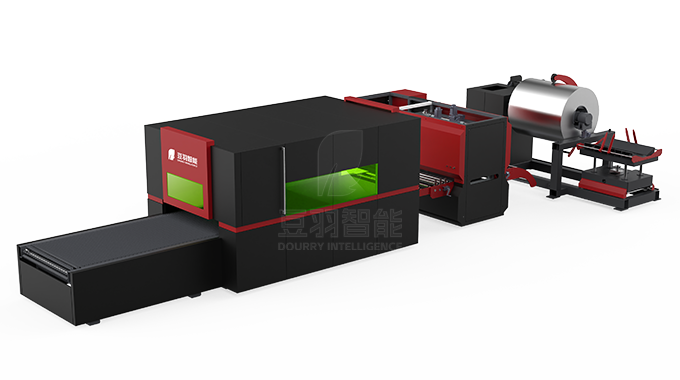

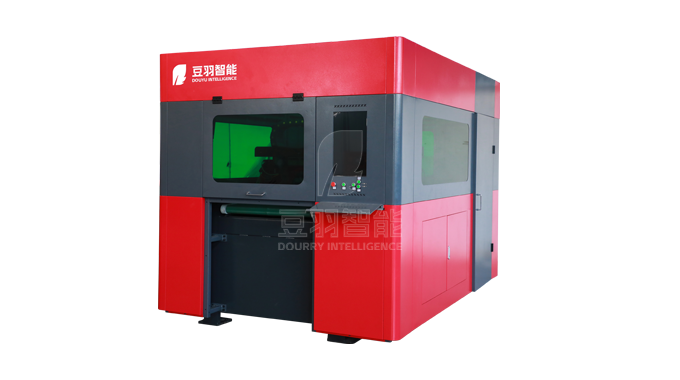

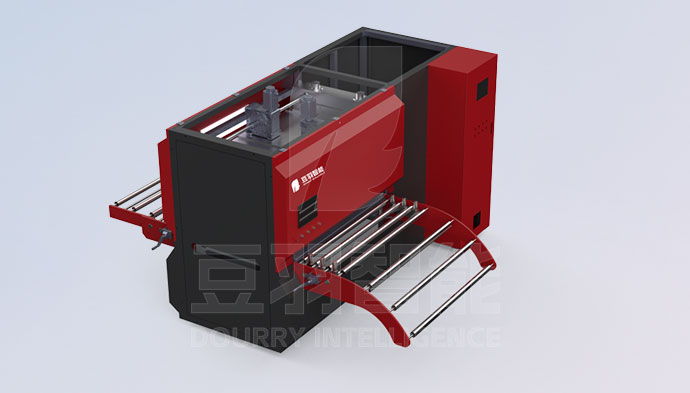

Get PriceThe fully automatic laser blanking line with fiber laser cutters is an efficient blanking production line developed for the sheet metal industry. It is especially suitable for occasions with large batches, high quality, and continuous operations. When the three-in-one feeder is running, the entire feeding device is driven by the motor and roller through the servo control system, resulting in higher transmission accuracy and more stable feeding. The laser uses an advanced special laser generator, equipped with a customized cutting head and a high-speed servo drive control system. The cutting speed is 20% higher than other products with the same power, improving production efficiency. Innovative optimized design realizes high-power and low-energy consumption production mode, saving 15% of energy consumption compared with similar products, and achieving better cost savings.

Applicable materials: cold rolled plate, standard plate, stainless steel

Material width: 1250mm/1500mm

Inner diameter of coil: φ480-530mm

Coil outer diameter: φ1320 mm

Weight Capacoty: ≤10t, ≤15t

It adopts 17 pieces rollers driven by servo motor and gear box.

No. of rollers: 17 pieces 8 upper rollers and 9 down rollers

Material of rollers: Alloy steel with quenched and tempered processing and hard chromium plating

Leveling accuracy: ≤1.5mm/㎡

| Machining area (L*W) | DC3015 | DC4020 |

|---|---|---|

| Machining area (L*W) | 3000mm×1500mm | 4000mm×2000mm |

| X-axis stroke | 3000mm | 4000mm |

| Y-axis stroke | 1500mm | 2000mm |

| Z-axis stroke | 200mm | 200mm |

| Positioning precision of X/Y axis | ±0.05mm/m | ±0.05mm/m |

| Repetitive positioning precision of X/Y axis | ±0.03mm | ±0.03mm |

| X/Y/Z axis Max. speed | 200m/min | 200m/min |

| Max. acceleration speed | 2.0g | 2.0g |

| Weight | 14t | 16t |

| Power | 35kW | 35kW |

| Equipment Covered Area | 14000*5250*2500 mm | 15000*6250*2500 mm |

| Rated power supply | 380V | 380V |

| Frequency | 50Hz | 50Hz |

| Applicable auxiliary gas | air, nitrogen, oxygen | air, nitrogen, oxygen |

If you are interested in our product, you can leave a message below and we will reply to you promptly.