DOURRY INTELLIGENT

Email: lydia@dourry.com

WhatsApp: +86-18768866269

In today's rapidly evolving technological landscape, the quality and efficiency of lab furniture production play a crucial role in ensuring the smooth progress of scientific research. A company has successfully utilized our laser cutting and welding machines to efficiently and precisely produce lab furniture, including experiment tables, providing strong support for the development of the scientific research field.

This enterprise has long been committed to the research and production of lab furniture, enjoying a certain market share. However, with the intensifying market competition and the diversification of customer demands, traditional production methods have become inadequate for meeting the enterprise's rapid development needs. To enhance production efficiency, reduce costs, and improve product quality, the enterprise decided to introduce advanced laser processing equipment.

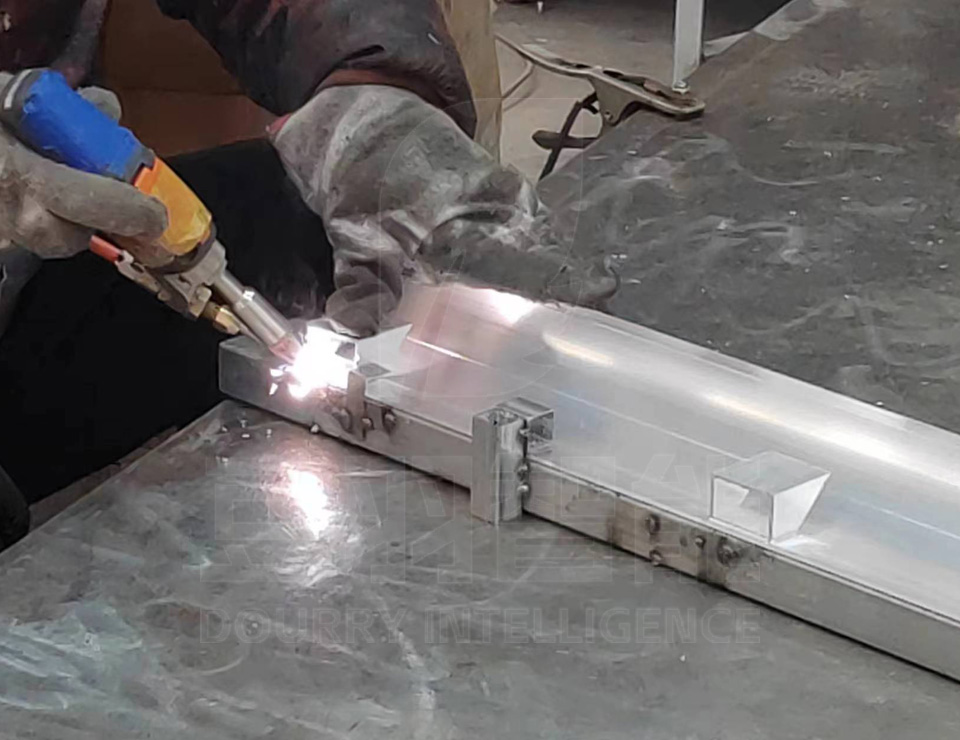

After conducting thorough market research and comparisons, the enterprise ultimately chose our laser cutting and welding machines. Both machines employ the latest laser technology and precision control systems, enabling high-speed and high-precision cutting and welding, making them ideal for the production of lab furniture.

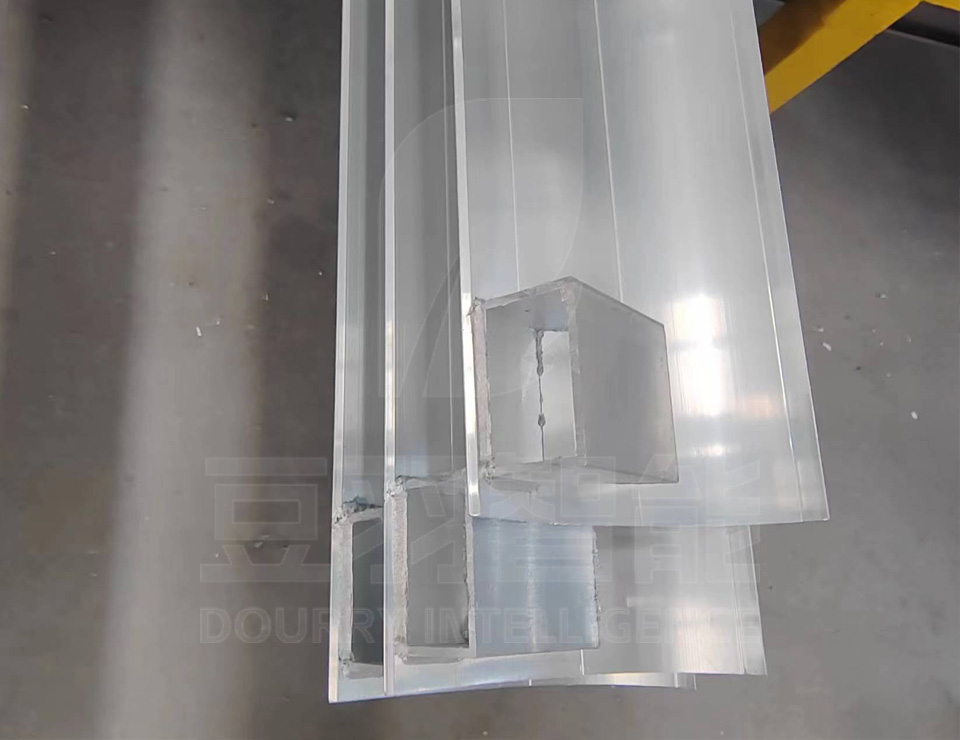

The introduction of the laser cutting machine has significantly improved the production processes related to cutting lab furniture components such as experiment table tops. With its high speed, precision, and flexibility, the laser cutting machine greatly enhances cutting efficiency and quality. Whether dealing with complex shapes or delicate contours, the laser cutting machine handles them effortlessly, reducing errors and burrs that often occur during traditional mechanical cutting. This not only improves production efficiency but also minimizes the need for subsequent processing and finishing work.

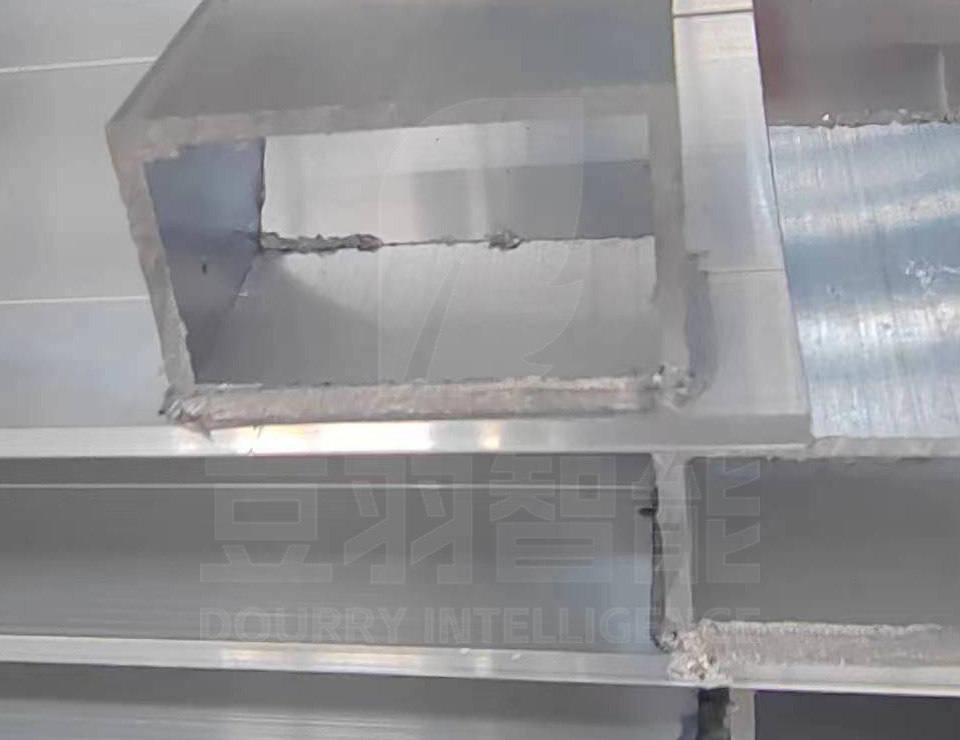

Meanwhile, the adoption of the laser welding machine has also revolutionized the enterprise's production processes. Compared to traditional welding methods, laser welding offers the advantages of beautiful welds, high strength, and a small heat-affected zone. In the production of lab furniture, the laser welding machine can precisely control welding parameters to achieve high-quality and efficient welding. This not only enhances the overall strength and stability of the lab furniture but also results in a more aesthetically pleasing appearance.

By incorporating our laser cutting and welding machines, the enterprise has successfully achieved efficient and precise production of lab furniture, including experiment tables. The significant boost in production efficiency has enabled the enterprise to respond more quickly to market demands and shorten delivery cycles. Additionally, the improvement in product quality has won the trust and praise of more customers.

Furthermore, the application of laser processing technology has opened up even more possibilities for the enterprise. Based on market demands and customer customization requirements, the enterprise can flexibly adjust its production processes and product designs to launch more innovative and competitive lab furniture products.

In conclusion, the introduction of our laser cutting and welding machines has provided the enterprise with significant competitive advantages in the field of lab furniture production. Looking ahead, with the continued development and improvement of laser technology, it is anticipated that this enterprise will achieve even greater successes in the lab furniture market. This successful case also fully demonstrates the exceptional performance and broad application prospects of our laser equipment, providing more enterprises with efficient and precise laser processing solutions.

If you are interested in our product, you can leave a message below and we will reply to you promptly.