DOURRY INTELLIGENT

Email: lydia@dourry.com

WhatsApp: +86-18768866269

aluminum plate, carbon steel plate, stainless steel plate, galvanized plate, yellow copper plate

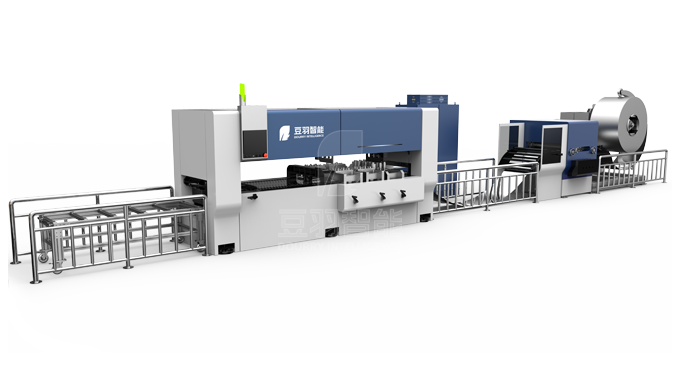

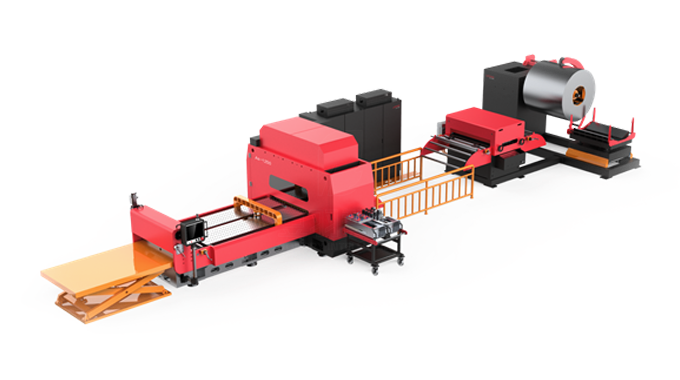

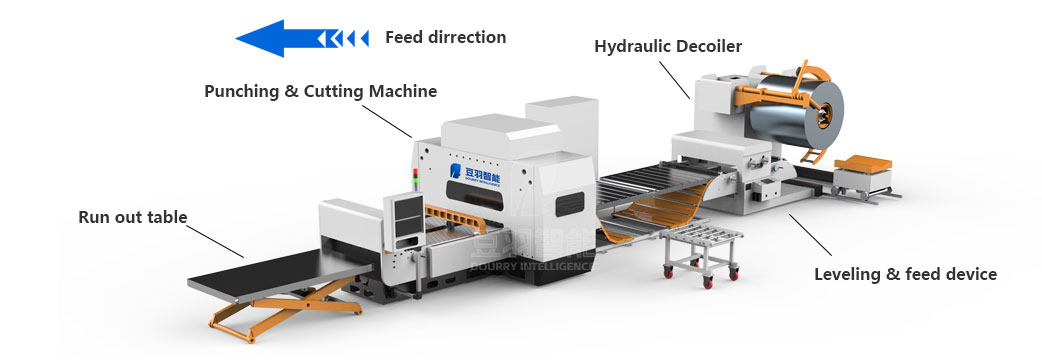

Get PriceFully Automatic Sheet Metal Flexible Punching And Shearing Production Line is the latest integrated, automated and intelligent equipment for metal plate production and processing developed by Dourry Intelligence Equipment. It can achieve 20m/min, 300 times/min. From the perspective of the development of the entire sheet metal processing industry, intelligence, automation, and flexibility represent the trend and development direction of sheet metal processing technology, and have great influence in the fields of intelligent equipment and industry 4.0. important application prospects. This punching and shearing production line has a high degree of automation and a wide processing range, which can meet the needs of different customer groups. It is widely used in sheet metal parts processing, such as batch processing of steel furniture, steel cabinets, electrical cabinets and other sheet metal parts.

Applicable materials: cold rolled plate, standard plate, stainless steel

Material width: 1250mm/1500mm

Inner diameter of coil: φ480-530mm

Coil outer diameter: φ1320 mm

Weight Capacoty: ≤10t, ≤15t

It adopts 17 pieces rollers driven by servo motor and gear box.

No. of rollers: 17 pieces 8 upper rollers and 9 down rollers

Material of rollers: Alloy steel with quenched and tempered processing and hard chromium plating

Leveling accuracy: ≤1.5mm/㎡

| Model | DP 1250 | DP 1000 | DP 700 |

|---|---|---|---|

| Feeding length and method | 1250mm/Precision ball screw | 1000mm/Precision ball screw | 700mm/Precision ball screw |

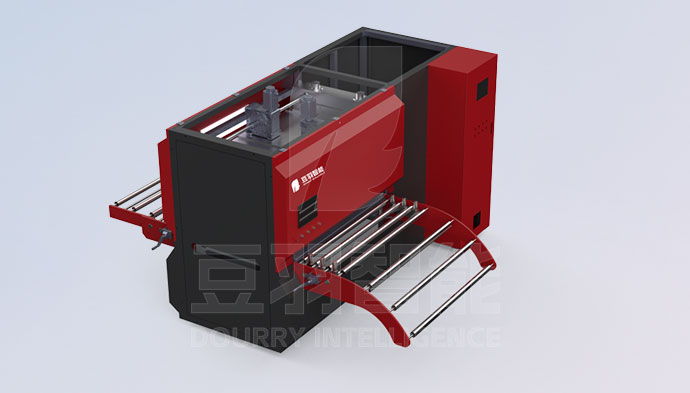

| Molds/Dies | 4 sets of standard thick turret box molds 2 sets of high-performance standard mold bases | ||

| Number of hits | 300cp/min | 300cp/min | 300cp/min |

| Mold changing trolley | 2 | 2 | 2 |

| Number of servo axes | 8+1+2 | 9+1+2 | 9+1+2 |

| Strike power | Servo | Servo | Servo |

| Material rack leveling | 3 in 1 | 3 in 1 | 3 in 1 |

| Raw material width | 300-1250mm(Customized) | 300-1000mm(Customized) | 300-700mm(Customized) |

| Max. thickest of raw material | 2mm | 2mm | 2mm |

| Engineering punching force | 300kN | 300kN | 300kN |

| Weight | 26t | 20t | 18t |

| Power | 100kW | 55kW | 55kW |

| Maximum punching | 90*180mm | 90*180mm | 90*180mm |

| Number of modules | There are 32 B stations and 8 D stations, which can accommodate 4 large squares or 8 small squares. | ||

| Punching accuracy | ±0.1mm | ±0.1mm | ±0.1mm |

| Diagonal accuracy | ±0.5mm | ±0.5mm | ±0.5mm |

If you are interested in our product, you can leave a message below and we will reply to you promptly.