DOURRY INTELLIGENT

Email: lydia@dourry.com

WhatsApp: +86-18768866269

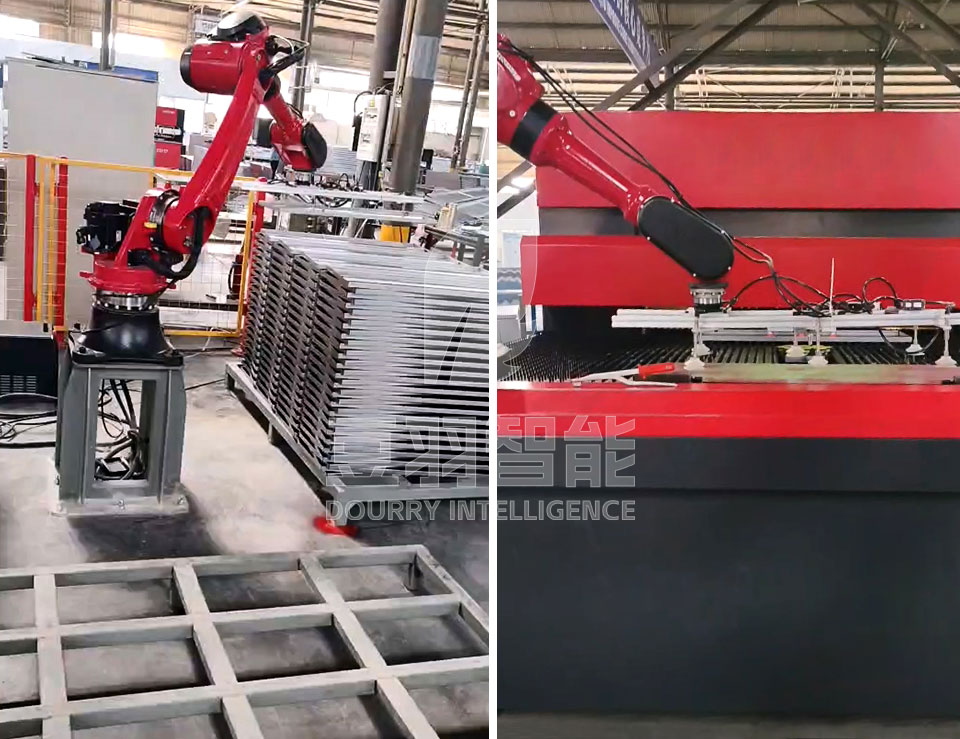

A Chinese manufacturing company is using an automated metal fabrication line to produce metal sheets. The line consists of three main components: a robot-assisted loading station, a folding center, and a welding station.

The robot-assisted loading station is responsible for loading the metal sheets onto the folding center. The robot uses a vacuum gripper to pick up the sheets from a conveyor belt and place them on the center.

The folding center is responsible for folding the metal sheets into the desired shape. The center uses a series of rollers to bend the sheets along a predetermined path.

The welding station is responsible for welding the metal sheets together. The station uses a robotic arm to apply welds at the specified locations.

The automated metal fabrication line offers a number of benefits over traditional manual methods. These benefits include:

Increased productivity: The line can produce more metal sheets per hour than a manual operation.

Improved quality: The line can produce more consistent and accurate results than a manual operation.

Reduced labor costs: The line requires fewer workers than a manual operation.

The automated metal fabrication line has helped the Chinese manufacturing company to improve its productivity, quality, and profitability.

The line is equipped with a safety system that prevents the robot from colliding with the metal sheets. The system uses a series of sensors to detect objects in the robot's path.

The line is also equipped with a quality control system that checks the welds for defects. The system uses a camera to inspect the welds for flaws.

If you are interested in our product, you can leave a message below and we will reply to you promptly.